MDI-96(3)

MDI-72

Beemet maximum demand indicator meters indicate the thermal /time characteristics of load and help audit efficient use of transformer stations and LT distribution feeders. The dimensions comply with the requirements of DIN 43700 and scales with DIN 43802. The performance confirms to IS 1248-83/93. The cases are made of polycarbonate.

The instrument pointer is accompanied by a red slave pointer which is driven by the torque of a bimetallic movement. This slave pointer remains at the max reading position for a successive reading and has to be reset to its default position with the help of a knob.

In the three-pointer MDI meter, a moving iron movement is housed in addition to the bimetallic spring, which indicates instantaneous and maximum demand currents.

Salient Features

• Rugged movement ensures sustained accuracy and reliability.

• Reset knob is easily accessible.

• Square bezel permits edge to edge mounting, allowing maximum use of panel space.

• Interchangeable dial for range portability.

• Almost linear scale for MI dial in 3-pointer.

• Clear scaling for easy reading.

General Specifications

| Accuracy | ±3.0% FSD (Bimetallic), ±1.5% FSD (Moving Iron) |

| Measurable Quantities | AC Current |

| Pointer deflection | 0 - 90º |

| Frequency | 45 – 60Hz |

| Thermal Time delay | 8 or 15 minutes |

| Moving Iron Response Time | ~2 seconds |

| Overload capacity | According to IS: 1248 / IEC 51 |

| Short duration | 10 times for 5s: 1 overload 10 times for 0.5s: 9 overloads |

| Continiously | 1.2 times rated voltage or current |

| Power Consumption @1A | <1.6VA (2-pointer), <2.5VA (3-pointer) |

| Power Consumption @5A | <2.5VA (2-pointer), <3.4VA (3-pointer) |

| Ambient Temperature @ use | 0 to 50°C |

| Operating Temperature | -10 to 55°C |

| Storage Temperature | -25 to 65°C |

| Relative Humidity | < 75% annual average, non-condensing |

Range Chart

| Model | Bimetallic | Moving Iron | For use on CT |

|---|---|---|---|

| MDI – 72, 96(3) | 1A | 1A | __ / 1A |

| MDI – 72, 96(3) | 5A | 5A | __ / 5A |

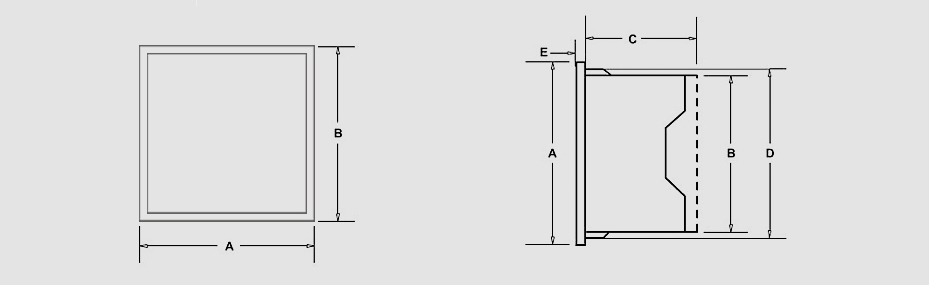

Dimensions

| Pointers | Model | Dimensions (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | Bimetallic Scale | Moving Iron Scale | Panel Cutout | |||

| Two Pointers | MDI-72 | 72 | 66 | 53 | 67.3 | 5.5 | 61 | – | 68x68 | |

| MDI-96 | 96 | 90 | 53 | 91.5 | 5.5 | 97 | – | 92x92 | ||

| Three Pointers | MDI-72(3) | 72 | 66 | 53 | 67.3 | 5.5 | 52 | 61 | 68x68 | |

| MDI-96(3) | 96 | 90 | 53 | 91.5 | 5.5 | 71 | 97 | 92x92 | ||

Wiring Diagrams

With direct connection

With Current Transformer

REGIONS WE SERVE

At BEEMET, we are dedicated to serving clients with high-quality MDI Meters across the globe. While we have a global presence, we’re proud to have clients in the following countries:

- UAE

- South Africa

- Qatar

- India

- Saudi Arabia

- Kuwait

- Oman

- USA

- UK

- China

- Europe

- South Korea

- Vietnam

- Japan

- Australia

FAQs

An MDI meter (also referred to as Maximum Demand Ammeter or Bimetallic Ammeter), is a device designed to measure and display the maximum electrical demand over a specific time interval. It helps users understand their peak energy consumption periods. It is available in 96×96, 72×72 and 48×48 sizes.

A standard energy meter measures total consumption, while an MDI meter focuses on identifying peak demand, providing insights into when a facility or equipment requires the most power.

Monitoring maximum demand is vital for businesses to optimise energy usage, avoid overloading systems during peak times, and potentially reduce electricity costs by managing demand more efficiently.

Yes, most MDI meters are designed for easy integration with existing energy management systems, allowing businesses to analyse data for energy efficiency planning.

Manufacturing, healthcare, and commercial facilities have the most benefit from MDI meters where they have fluctuating energy demands. They help these sectors plan their energy consumption better.