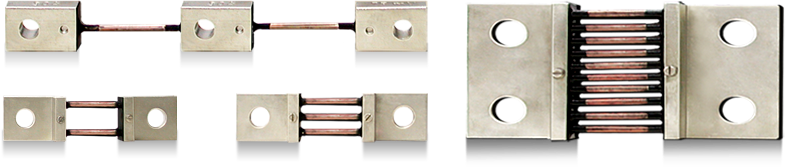

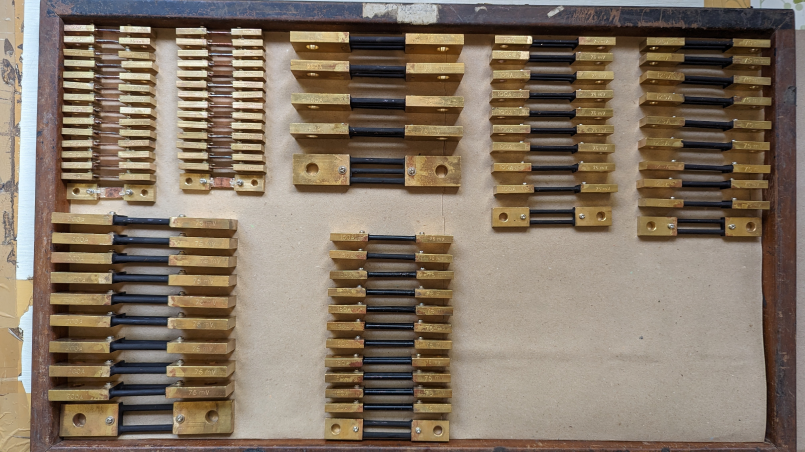

Shunts

Beemet Instruments is one of the leading ammeter shunts manufacturers and exporters in India. Our DC shunts are made in-house by our expert team of engineers and are designed to the highest specifications.

They are manufactured with high-quality Manganin wire. Manganin is the best alloy for DC shunts application with a temperature coefficient of only 10ppm.

Beemet’s ammeter shunts provide a high level of stability and confirm IS:1248 specifications. Furthermore, our DC shunts are approved by DOT (CACT) in Bangalore. Our Shunts are available in various configurations and can be customized to suit your requirements.

Whether you need a DC shunt for industrial, automotive, or other applications, Beemet has the right solution for you. Our DC shunts are even compatible with the EVs.

Check our blogs on Shunts: Shunts – All You Need To Know

Salient Features

• Very low temperature coefficient.

• In-line bus bar mounting.

• Withstands high overload.

• Ruggedly constructed.

• Shock & vibration proof.

• Long term stability.

• Custom made shunts available.

• Very low temperature coefficient.

• In-line bus bar mounting.

• Withstands high overload.

• Ruggedly constructed.

• Shock & vibration proof.

• Long term stability.

• Custom made shunts available.

General Specifications

| Milli Volt Drop | Standard: 50mV, 60mV, 75mV Other mV outputs available on request |

| Accuracy | ± 0.5% / ±1.0% |

| Overload Capacity | According to IS: 1248 / IEC 51 |

| Short duration | 10 times for 5s: 1 overload |

| Continuously | 20% rated current |

| Temperature Coefficient | 0.002% per °C |

| Ambient Temperature | Calibration at 23°C |

| Operating Temperature | -10 to 55°C |

| Storage Temperature | -20 to 70°C |

| Maximum load | Not to exceed 0.1% of the nominal current rating for specified accuracy |

Range Chart

| I Section | 1A – 30A, 40A, 50A, 60A, 75A, 80A, 100A, 120A, 150A, 200A, 250A, 300A |

| L Section | 400A, 500A, 600A, 750A, 800A, 1000A, 1200A, 1500A, 2000A, 2500A, 3000A |

| T Section | 4000A, 5000A, 6000A, 7500A, 8000A, 10000A, 12000A, 15000A |

Installation

• Shunts may be mounted horizontally or vertically. Horizontal mounting gives the best heat dissipation.

• Utilize the full end block surface area.

• Ample ventilation should be provided.

• Busbar should be adequately rated, cleaned and coated with a thin layer of silicon grease applied to the contact surface area.

• Bolts & nuts must be carefully tightened.

Regions We Serve

With our shunts produced on a global scale, we continue to serve clients with unmatched quality and reliability, we are privileged to have a diverse client base across numerous countries:

- UAE

- South Africa

- Qatar

- India

- Saudi Arabia

- Kuwait

- Oman

- USA

- UK

- China

- Europe

- South Korea

- Vietnam

- Japan

- Australia

FAQs

An ammeter shunt is a device that is used to measure the current in an electrical circuit by creating a low resistance path for a portion of the current to flow through, allowing for an accurate measurement to be taken.

Want to know more?

Please read our blog

The most common types of ammeter shunts are precision, high current, and high voltage ammeter shunts

The maximum current capacity of an ammeter shunt depends on the specific model and manufacturer, but can range from a few milliamperes to several kiloamperes.

The accuracy of an ammeter shunt depends on the manufacturer and model, but they are generally accurate within a few percent of the reading.

Yes, some ammeter shunts are designed to handle high temperatures and harsh environments. The manufacturer should specify the temperature range for a particular model.

Yes, some ammeter shunt manufacturers offer custom wiring and configurations for specific applications.

Yes, ammeter shunts can be used in safety critical applications, but it is important to choose a high-quality, reliable product from a reputable manufacturer and to have the device properly installed and maintained.