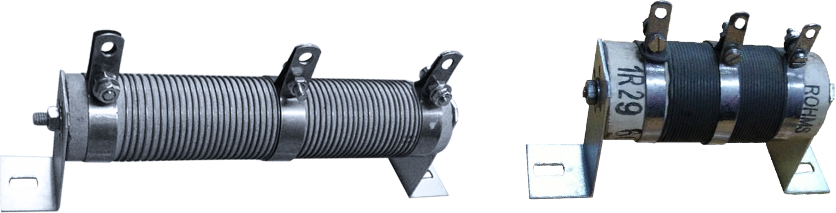

These wire-wound resistors are manufactured with the highest grade Nickel Chrome and Copper Nickel alloy wires to provide mechanically uniform tension and spacing.

Salient Features

• Spot welded joints for reliability.

• Low temperature co-efficient, low surface temperature.

• Brackets available for horizontal as well as vertical mountings.

• Exceptional stability and performance.

performance data

| Test | Procedure | Requirements |

|---|---|---|

| Short Time Overload | 10 X Rated power for 5 sec. | Δ R / R max : ±(2.0 +0.05 Ώ) |

| Dielectric Withstanding Voltage | 1000 VAC, from terminal to mounting hardware. | No flash over or breakdown should observed |

| Endurance @ 25°C | 1000hrs. Load with Pn (power nominal) 1.5 hr. ON & 0.5 hr. OFF | No visual damange Δ R / R max : ±(5.0 +0.01 Ώ) |

| Temperature Rise Test | Horizontally mounted, loaded with Pn | Hot spot temperature less than maximum body temperature |

| Temperature Coefficient | At 25 /-55/25 0C & 25/ 150/ 25 °C | Within specified limits |

| Insulation Resistance | V – Block method for 1 minute duration at 500 V dc | > 103 MΏ |

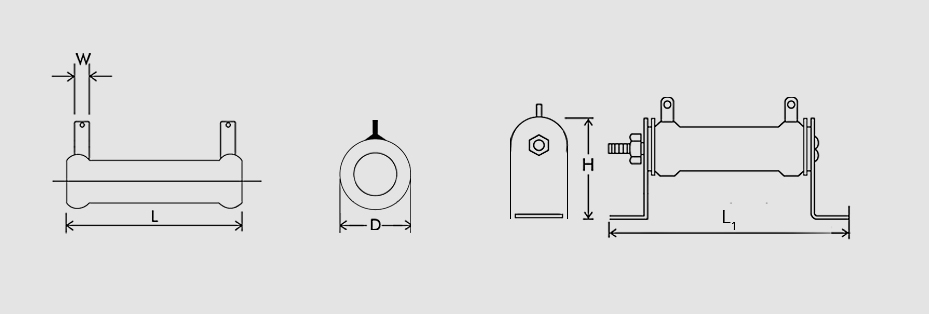

Dimensions

| Watts | Dimensions (mm) | Resistance Range | ||||

|---|---|---|---|---|---|---|

| L | W | D | L' | H | ||

| 25W | 65 | 6 | 16 | 83 | 33 | 0.1E–3K |

| 30W | 76 | 6 | 16 | 100 | 33 | 0.1E–3 |

| 40W | 102 | 6 | 16 | 125 | 33 | 0.1E–3K |

| 40W | 102 | 6 | 16 | 125 | 33 | 0.1E–3K |

| 50W | 100 | 6 | 20 | 125 | 33 | 0.1E–3K |

| 75W | 127 | 7.9 | 25 | 170 | 40 | 0.1E–3K |

| 100W | 150 | 9.5 | 30 | 182 | 50 | 0.1E–3K |

| 150W | 175 | 9.5 | 34 | 201 | 60 | 0.1E–3K |

| 200W | 254 | 9.5 | 33 | 280 | 60 | 0.1E–5K |

| 250W | 305 | 9.5 | 30 | 345 | 60 | 0.1E–5K |

| 300W | 305 | 9.5 | 38 | 345 | 60 | 0.1E–5K |

| 400W | 305 | 9.5 | 50 | 345 | 75 | 0.1E–5K |

| 500W | 350 | 9.5 | 50 | 385 | 75 | 0.1E–5K |

| 600W | 380 | 9.5 | 76 | 420 | 75 | 0.1E–5K |

| 750W | 330 | 9.5 | 76 | 370 | 100 | 0.1E–5K |

| 1000W | 407 | 9.5 | 76 | 445 | 100 | 0.1E–5K |

| 1250W | 457 | 9.5 | 76 | 495 | 103 | 0.1E–5K |

| 1500W | 457 | 9.5 | 90 | 510 | 130 | 0.1E–5K |

FAQ

Resistors are electrical components that help control voltage and current levels by limiting the flow of electric current in a circuit. Resistors come in various types, including fixed and variable resistors, each serving different functions in electronic devices.h

A wire wound resistor is used to limit or regulate the flow of electrical current in a circuit. Common applications include:

- Power Supplies

- Audio Equipment

- Measurement Devices

- Braking Systems

- Voltage division

- Current limiting

- Load resistance in both AC and DC circuits

Wire wound resistors are known for their durability, stability, and accuracy. This makes them ideal for use to handle high power loads while maintaining precise resistance values. These resistors also offer superior temperature stability and low noise characteristics compared to other types of resistors making them suitable for critical applications in various electronic devices.

To identify wire wound resistors, look for these key features:

- Appearance

- Labels and Markings

- Construction

- Size

Wire wound resistors possess several key properties such as:

- High Power Rating

- Precision

- Temperature Stability

- Low Noise

To read a wire wound resistor, look for:

- Printed Values: Look for numbers and symbols that indicate these values.

- Color Bands: With 3 different bands each depicting different digits are to be noted.

- Power Rating: Indicated by the physical size of the resistor

- Consult Documentation: Datasheets are provided for detailed information.

Carbon resistors use carbon composition to create resistance which makes them less precise and more susceptible to temperature changes whereas wire wound resistors use metal wire which provides greater accuracy, better stability under varying conditions, and higher power ratings.

The advantage of a wire wound resistor includes:

- High Power Handling

- Precision

- Temperature Stability

- Durability

Wire wound resistors find applications, such as:

- Power Supplies

- Audio Equipment

- Measurement Devices

- Braking Systems

- Industrial Machinery

- Heating Elements

Wire wound resistors are fixed resistors designed to provide a specific resistance value that does not change during operation. However, some designs can be variable, allowing users to adjust the resistance within a defined range for specific applications.