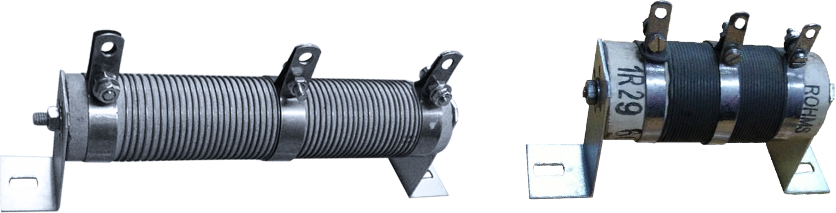

These wire-wound resistors are manufactured with the highest grade Nickel Chrome and Copper Nickel alloy wires to provide mechanically uniform tension and spacing.

Salient Features

• Spot welded joints for reliability.

• Low temperature co-efficient, low surface temperature.

• Brackets available for horizontal as well as vertical mountings.

• Exceptional stability and performance.

performance data

| Test | Procedure | Requirements |

|---|---|---|

| Short Time Overload | 10 X Rated power for 5 sec. | Δ R / R max : ±(2.0 +0.05 Ώ) |

| Dielectric Withstanding Voltage | 1000 VAC, from terminal to mounting hardware. | No flash over or breakdown should observed |

| Endurance @ 25°C | 1000hrs. Load with Pn (power nominal) 1.5 hr. ON & 0.5 hr. OFF | No visual damange Δ R / R max : ±(5.0 +0.01 Ώ) |

| Temperature Rise Test | Horizontally mounted, loaded with Pn | Hot spot temperature less than maximum body temperature |

| Temperature Coefficient | At 25 /-55/25 0C & 25/ 150/ 25 °C | Within specified limits |

| Insulation Resistance | V – Block method for 1 minute duration at 500 V dc | > 103 MΏ |

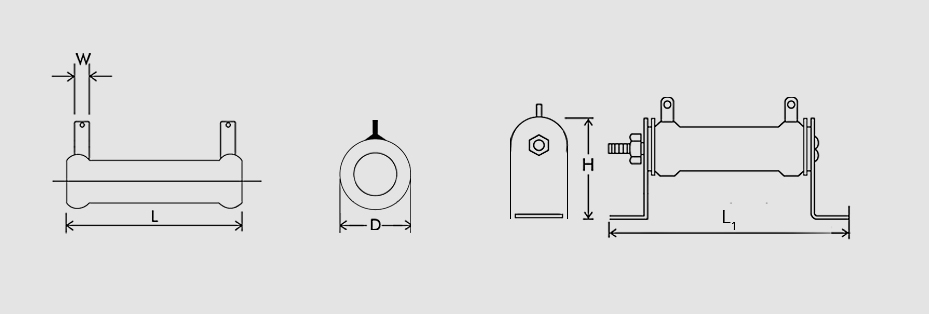

Dimensions

| Watts | Dimensions (mm) | Resistance Range | ||||

|---|---|---|---|---|---|---|

| L | W | D | L' | H | ||

| 25W | 65 | 6 | 16 | 83 | 33 | 0.1E–3K |

| 30W | 76 | 6 | 16 | 100 | 33 | 0.1E–3 |

| 40W | 102 | 6 | 16 | 125 | 33 | 0.1E–3K |

| 40W | 102 | 6 | 16 | 125 | 33 | 0.1E–3K |

| 50W | 100 | 6 | 20 | 125 | 33 | 0.1E–3K |

| 75W | 127 | 7.9 | 25 | 170 | 40 | 0.1E–3K |

| 100W | 150 | 9.5 | 30 | 182 | 50 | 0.1E–3K |

| 150W | 175 | 9.5 | 34 | 201 | 60 | 0.1E–3K |

| 200W | 254 | 9.5 | 33 | 280 | 60 | 0.1E–5K |

| 250W | 305 | 9.5 | 30 | 345 | 60 | 0.1E–5K |

| 300W | 305 | 9.5 | 38 | 345 | 60 | 0.1E–5K |

| 400W | 305 | 9.5 | 50 | 345 | 75 | 0.1E–5K |

| 500W | 350 | 9.5 | 50 | 385 | 75 | 0.1E–5K |

| 600W | 380 | 9.5 | 76 | 420 | 75 | 0.1E–5K |

| 750W | 330 | 9.5 | 76 | 370 | 100 | 0.1E–5K |

| 1000W | 407 | 9.5 | 76 | 445 | 100 | 0.1E–5K |

| 1250W | 457 | 9.5 | 76 | 495 | 103 | 0.1E–5K |

| 1500W | 457 | 9.5 | 90 | 510 | 130 | 0.1E–5K |