Panel meters are devices that display the input signal in analog or digital format. Panel meters are an integral part of industries that require monitoring or controlling the equipment daily. Modern panel meters are equipped with cutting-edge features including alarms, data transmission through various mediums, etc.

The fundamental working principle goes like this: a sample of voltage or current from the signal is taken, and a visual representation is produced. While current measurements are often made in series, voltage measurements are typically made across the load. In high-power systems, additional instruments like current/voltage transformers are employed for high-magnitude measurements.

Motor current monitoring is a typical use for panel meters. In an industrial application, a motor that drives pumps or fans will have certain line requirements. For instance, a filter obstruction may cause the fan to become more resistant, which, if left untreated, can cause a number of issues, most notably a halt in operations.

In contrast, a broken belt may cause a decline in motor output current, which needs to be fixed right away to restore productivity. Voltage and current measurements can be made using a potential or current transformer, and the results can then be seen on a panel meter.

The two major types of panel meters are digital panel meters and analog panel meters.

What Are Panel Meters?

Panel meters are displays that are designed to be put inside of a panel, like a control panel. Typically, they read some kind of input—a voltage, current, or resistance—and digitally display its value. This input often consists of a sensor measurement that is converted into a temperature, pressure, or other system variable and displayed.

These meters can also work as straightforward controllers, tripping a switch or carrying out a simple function when the reading reaches a predetermined measurement.

Types of Panel Meters

Apart from the functionality, types of digital panel meters vary depending on the type of display and lighting technology used.

Display

- Numeric: Only numbers are displayed. Since the purpose is to display numeric values of the input, digital panel meters commonly come with numeric displays.

- Alpha-numeric: Letters and numbers are displayed. The idea is to serve more details regarding the values displayed, such as the measurement reading’s channel, units, etc.

Lightning Technology

- Led Displays: consists of light-emitting diodes that light up and are visible in the dark.

- LCD Displays: made of liquid crystal displays, these are dark/black digits across a blank grey or green screen and require a backlight to be visible in the dark.

Signal Input Type

Digital panel meters must be designed to accept the analog input sent to them in order to function properly. These inputs can be of various types:

- AC Voltage: input acquired in the measurable form of AC Voltage in VAC (Volts AC).

- AC Current: input acquired in the measurable form of AC Current in AC (AC Amperes) or mA AC (AC Milliamperes). Panel amp meters are widely used in applications that require accurate monitoring of AC or DC current, ensuring efficient operation of electrical systems and helping to detect any abnormalities in current flow.

- AC Power: input acquired in an adjustable range of current, voltage and/or frequency.

- DC Voltage: input acquired in the measurable form of DC Voltage in VAC (Volts AC).

- DC Current: input acquired in the measurable form of DC Current in A AC (AC Amperes) or mA AC (AC Milliamperes).

- DC Power: input acquired in an adjustable range of current, voltage and/or frequency.

- Temperature: input acquired through a temperature sensor like a thermistor, RTD or thermocouple.

- Pressure: input acquired from elements that measure a change in resistance, such as strain gauges or piezoresistive sensors.

Functions of Digital Panel Meters

The various functions of digital panel meters determine their utility in different settings.

- Basic Display Output

All digital panel meters’ fundamental task is to translate an input signal into a displayed value. A sensor that is part of the system provides input to the device via the panel the meter is connected to. The control panel provides power and inputs for the meter display. - Additional Outputs

- Analog Functionality can produce an analogue output for analog devices, such as a variable voltage or current, that is proportional to the input signal.

- Data Interface Functionality allows interaction with the information displayed for data analysis.

- Set Point Functionality allows users to establish input values for alarms of simple control operations. Depending on the design of the meter and panel, these on/off functions correlate to solid-state or electromechanical relay outputs.

If you are looking to read more on voltmeters and ammeters, you can check out our dedicated guides on these topics.

Features of Digital Panel Meters

Following is the list of extra features incorporated by digital panel meters for the added functionality:

- Alarms (either visual or audible) may be built in the meter to signal when set points or limits are reached.

- Set points options allow you to set control limits or set points for process variables like speed, temperature, humidity or pressure. In a heating application, the device sends an ON control signal when the temperature falls below the set point and an OFF control signal when the set point temperature is reached or surpassed.

- On/off control enables the meter to direct an on/off output signal to start or stop a process unit (over, motor or fan) using relays, open collector transistors or other electronic devices. One of the most basic methods for process control is on-off, bang-bang, or limit control.

- Adjustable displays enable the meter to be modified to show various displays.

- Additional channels allow meters to receive and interpret many signals from various sources.

- USB/serial ports allow meters to be connected to other devices, including computers or data analysis tools, using USB/serial ports.

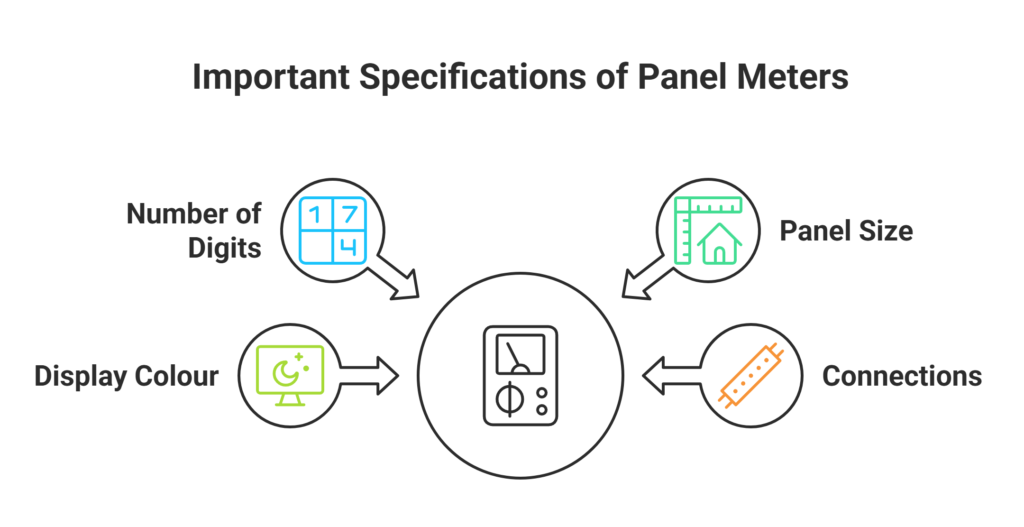

Important Specifications of Panel Meters

Digital panel meters can be of various types. Following are some specifications to take into account:

- Number of Digits

The number of digits represents how many digits appear in the display output. Depending on the level of accuracy required, this number should be fewer than or equal to the number of significant figures in the signal input.

The first or last digit in meters that can display half-digits (such as 4.5 or 2.5 digits) can only be “1” or off, or “5” or off. This “half” digit enables the display of intermediate numbers (100.5 vs. 100_) or an extension of the display’s upper limits (1000 vs. _999).

- Size

The device’s physical compatibility with the panel it is to be mounted on depends on the size of the panel face. Typically, face sizes are described by length and width and are measured in inches (in) or millimetres (mm). Although most panels will accept standard depths related to the face size, sometimes the depth of the meter and the dimensions of the cutout need to be considered. The display should also be large enough for the user to read the numbers and letters when mounted. - Colour

Certain colours are intended for display on digital panel meters. In LCD meters, the backlight hidden behind the black numbers determines the colour and in LED meters, the type of diodes incorporated determines the colour. Red is the standard LED colour and LCDs often lack backlighting (no colour). There are multicolour choices, which are especially helpful when using multiple displays or channels. Users may find it easier to recognise the measurements by setting one colour to each display. - Connections

The physical connections (such as screw connectors) required for a stable mounting to the panel, as well as the electrical inputs and outputs, are all included in the connections for digital display meters. Panel meter connectors play a crucial role in ensuring a secure and reliable connection, contributing to the accuracy of the measurements displayed. These connections have to work with the associated control panel’s design and features.

Applications of Digital Panel Meter

Digital panel meters are widely used to monitor motor currents, over temperature and pressures. They also come in handy for the following tasks:

- Welding Current

It is challenging to perform nondestructive weld quality verification, thus it is crucial to keep an eye on the welding parameters. It is feasible to employ a shunt to reduce the current and voltage utilised at the welder to a level that a digital panel meter can handle, allowing it to serve as a process meter. - Protection of 3-Phase Motors

Voltage fluctuations across the phases can be sensitive to large industrial motors. Digital panel meters can be configured to function as a frequency meter and allow monitoring of incoming voltage, enabling quick detection of any faults. Alarms can be set off as needed to detect voltage imbalances across the lines, high or low voltage, and even dropped lines. - Cooling Water TemperatureWater pumped through the tooling of injection moulding machines is frequently used to cool and solidify the plastic. Both the water’s temperature and flow rate affect predictable cooling. The temperatures of the water before and after it goes through the tool can be seen on a digital panel meter.

Bottom Line

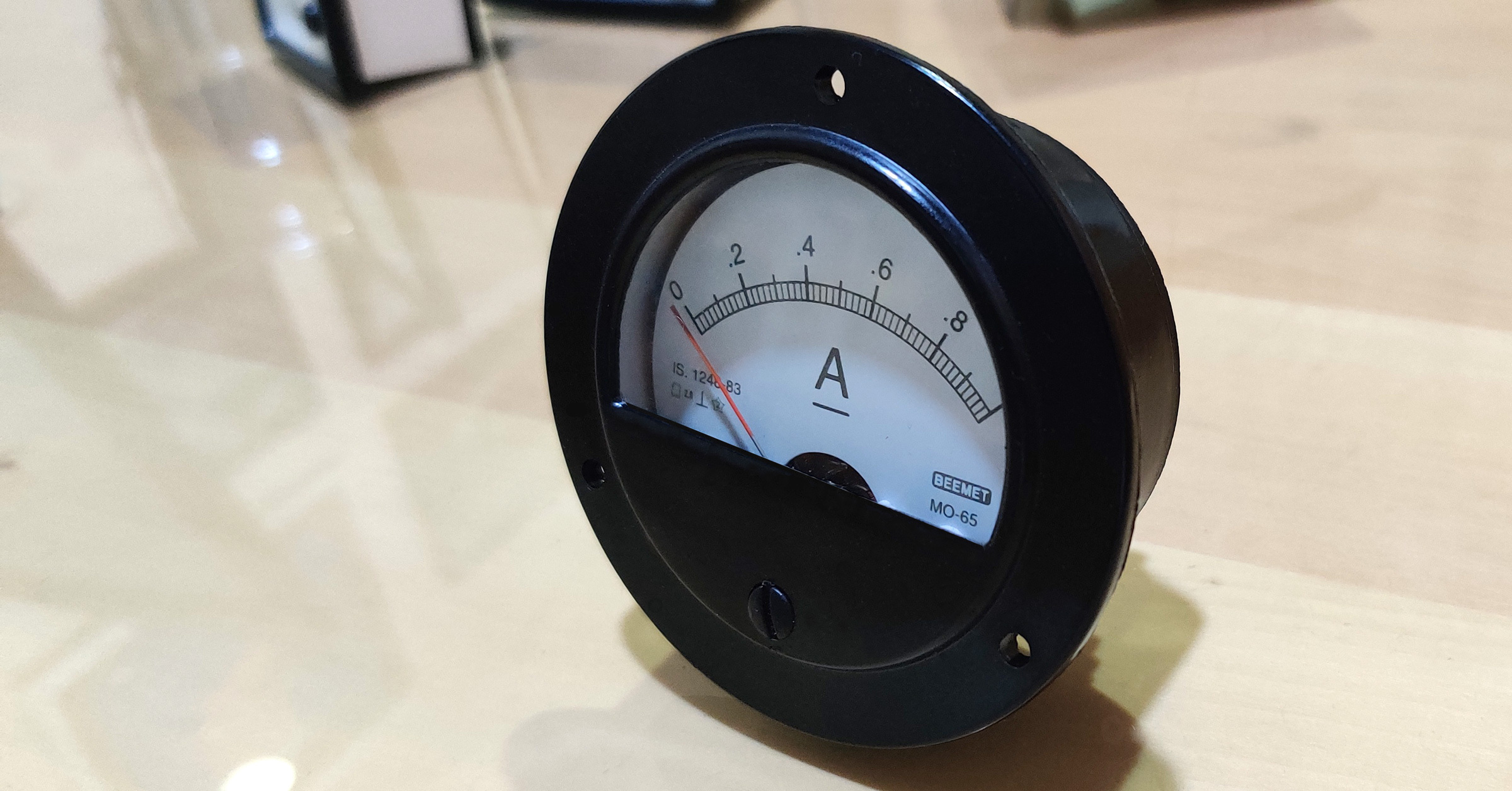

A pioneer in electrical measuring instruments, Beemet’s panel meters have much more value to offer than the little you invest in them. We have a wide range of analog and digital panel meters that are rolled up with the finest of materials, a built-in transducer, and all of it in a handy, compatible size.

FAQs

An analog panel meter uses a needle to show the value, whereas in digital ones the resulting numbers appear over a screen.

With a proper LCD readout, digital panel meters are generally seen as more modern and better than analog panel meters.

Digital panel meters are more accurate and reduce the room for errors, in contrast to analog panel meters. Digitizing analog meters allows for enhanced precision, ensuring that readings are displayed without the interpolation errors commonly associated with traditional analog meters. They reduce reading and interpolation errors and their portable size makes it easy to carry them anywhere.